JRMGE / Vol 15 / Issue 1

Various admixtures to mitigate the long-term strength retrogression of Portland cement cured under high pressure and high temperature conditions

Jiankun Qin, Xueyu Pang, Ashok Santra, Guodong Cheng, Hailong Li

Show More

a School of Petroleum Engineering, China University of Petroleum (East China), Qingdao, 266580, China

b Key Laboratory of Unconventional Oil & Gas Development (China University of Petroleum (East China)), Ministry of Education, Qingdao, 266580, China

c Drilling Technology Team, Aramco Americas: Aramco Research Center, 16300 Park Row Drive, Houston, TX, 77084, USA

2023, 15(1): 191-203. doi:10.1016/j.jrmge.2022.02.005

Received: 2021-09-30 / Revised: 2021-12-10 / Accepted: 2022-02-23 / Available online: 2022-03-31

2023, 15(1): 191-203.

doi:10.1016/j.jrmge.2022.02.005

Received: 2021-09-30

Revised: 2021-12-10

Accepted: 2022-02-23

Available online: 2022-03-31

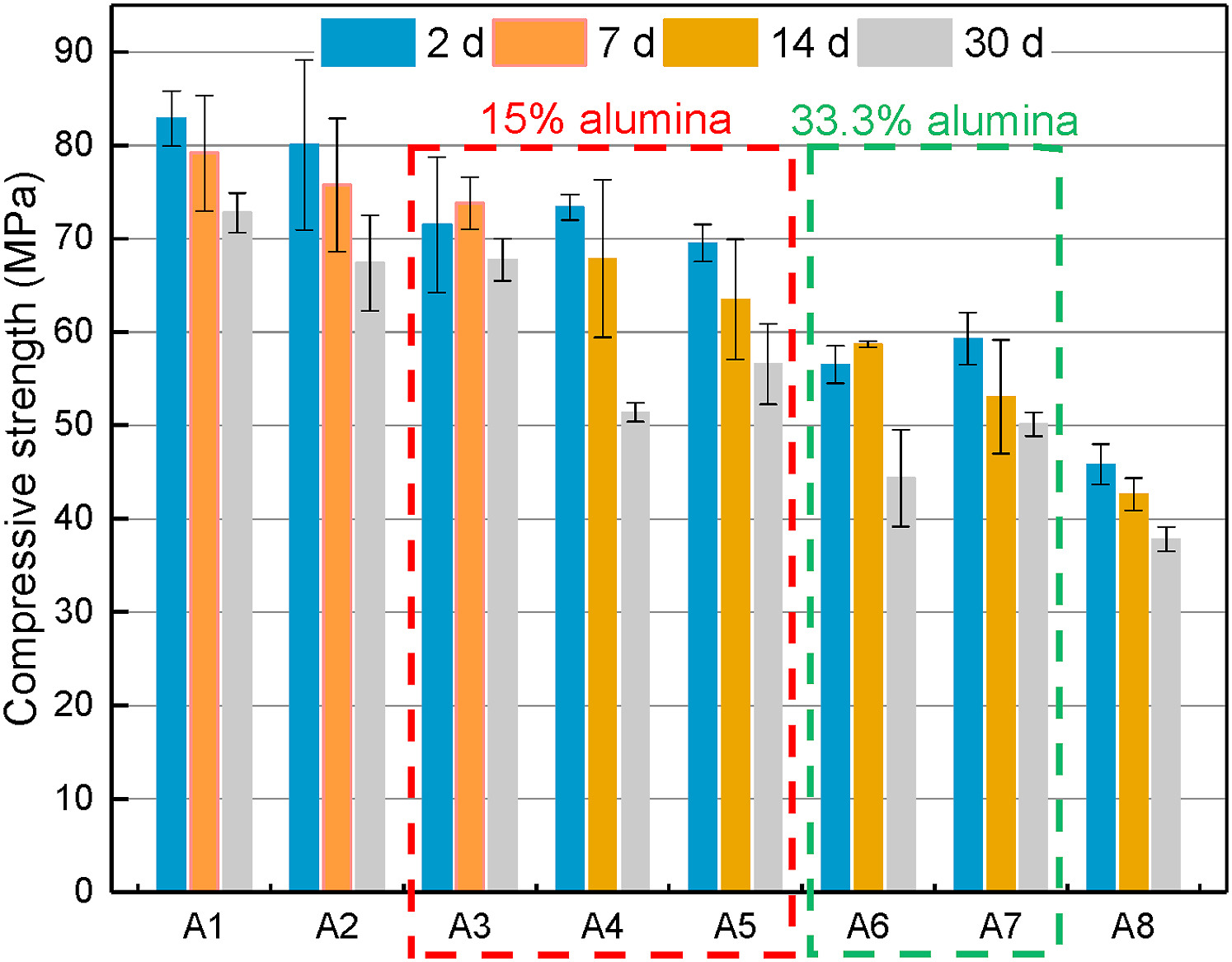

In order to investigate the problem of long-term strength retrogression in oil well cement systems exposed to high pressure and high temperature (HPHT) curing conditions, various influencing factors, including cement sources, particle sizes of silica flour, and additions of silica fume, alumina, colloidal iron oxide and nano-graphene, were investigated. To simulate the environment of cementing geothermal wells and deep wells, cement slurries were directly cured at 50 MPa and 200 °C. Mineral compositions (as determined by X-ray diffraction Rietveld refinement), water permeability, compressive strength and Young's modulus were used to evaluate the qualities of the set cement. Short-term curing (2–30 d) test results indicated that the adoption of 6 μm ultrafine crystalline silica played the most important role in stabilizing the mechanical properties of oil well cement systems, while the addition of silica fume had a detrimental effect on strength stability. Long-term curing (2–180 d) test results indicated that nano-graphene could stabilize the Young’s modulus of oil well cement systems. However, none of the admixtures studied here can completely prevent the strength retrogression phenomenon due to their inability to stop the conversion of amorphous to crystalline phases.

Keywords: High pressure and high temperature (HPHT), Strength retrogression, Young’s modulus, Water permeability, Rietveld method

Show Figure(s)

Supplementary Material

Share and Cite

Jiankun Qin, Xueyu Pang, Ashok Santra, Guodong Cheng, Hailong Li, 2023. Various admixtures to mitigate the long-term strength retrogression of Portland cement cured under high pressure and high temperature conditions. J. Rock Mech. Geotech. Eng. 15 (1), 191-203.

Article Data

Author(s) Information

Xueyu Pang

Xueyu Pang obtained his BE degree in Civil Engineering from Ocean University of China in 2005, and his MSc degree in Civil Engineering from Villanova University, USA, in 2007. He obtained his PhD in Civil Engineering from Columbia University in the City of New York, USA, in 2011. He was Senior Technical Professional with Halliburton from 2011 to 2017, and Principal Technical Professional with Halliburton from 2017 to 2018. He joined China University of Petroleum (East China) as a professor in 2018 and served as the director of Oil and Gas Well Engineering Research Institute since 2021. His research interests include (1) Cement chemistry: hydration kinetics, modeling, additive chemistry; (2) Characterization of oil well cement at high temperature and high pressure conditions: hydration, rheological properties, physico-mechanical properties, strength retrogression; (3) Optimization of cement-based materials: nanomaterial additives, geopolymer systems, elastic cement systems, etc.