JRMGE / Vol 16 / Issue 2

Effect of fracture fluid flowback on shale microfractures using CT scanning

Jiale He, Zhihong Zhao, Yiran Geng, Yuping Chen, Jianchun Guo, Cong Lu, Shouyi Wang, Xueliang Han, Jun Zhang

Show More

a State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, Southwest Petroleum University, Chengdu, 610500, China

b Key Laboratory of Thermo-Fluid Science and Engineering of Ministry of Education, School of Energy and Power Engineering, Xi’an Jiaotong University, Xi’an,

710049, China

c Drilling Test Engineering Department of Longdong Oil and Gas Development Company, Changqing Oilfield, PetroChina Company Limited, Qingyang, 745000, China

d Tight Oil and Gas Exploration and Development Project Department, PetroChina Southwest Oil and Gas Field Company, Chengdu, 610056, China

e No. 11 Oil Production Plant, Changqing Oilfield Company, PetroChina Company Limited, Qingyang, 745000, China

2024, 16(2): 426-436. doi:10.1016/j.jrmge.2023.07.006

Received: 2022-12-23 / Revised: 2023-04-23 / Accepted: 2023-07-09 / Available online: 2023-08-26

2024, 16(2): 426-436.

doi:10.1016/j.jrmge.2023.07.006

Received: 2022-12-23

Revised: 2023-04-23

Accepted: 2023-07-09

Available online: 2023-08-26

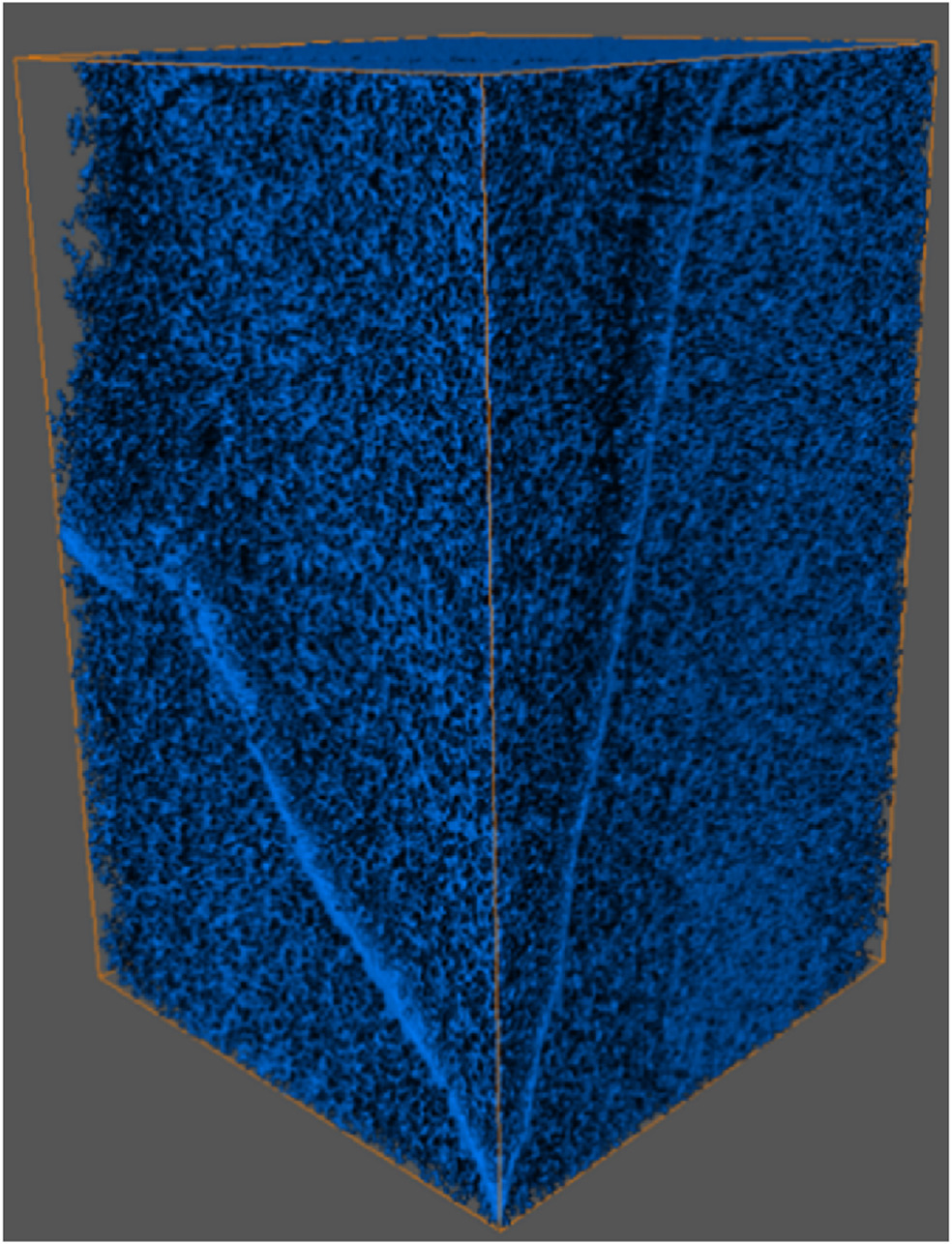

The field data of shale fracturing demonstrate that the flowback performance of fracturing fluid is different from that of conventional reservoirs, where the flowback rate of shale fracturing fluid is lower than that of conventional reservoirs. At the early stage of flowback, there is no single-phase flow of the liquid phase in shale, but rather a gas-water two-phase flow, such that the single-phase flow model for tight oil and gas reservoirs is not applicable. In this study, pores and microfractures are extracted based on the experimental results of computed tomography (CT) scanning, and a spatial model of microfractures is established. Then, the influence of rough microfracture surfaces on the flow is corrected using the modified cubic law, which was modified by introducing the average deviation of the microfracture height as a roughness factor to consider the influence of microfracture surface roughness. The flow in the fracture network is simulated using the modified cubic law and the lattice Boltzmann method (LBM). The results obtained demonstrate that most of the fracturing fluid is retained in the shale microfractures, which explains the low fracturing fluid flowback rate in shale hydraulic fracturing.

Keywords: Shale, Flowback of fracturing fluid, Microfracture, Lattice Boltzmann method (LBM)

Article Data

Author(s) Information

Zhihong Zhao

Zhihong Zhao obtained his BEng and MEng degrees in Southwest Petroleum University, China, in 2005 and 2008, respectively, and his PhD in the same university in 2011. He was affiliated as scientific staff with Geological Resources and Geological Engineering of Southwest Petroleum University from 2012 to 2013, and Laboratory of Reservoir Stimulation and Reconstruction of Southwest Petroleum University, since 2013. His research interests include (1) experimental investigations and numerical simulation of hydraulic fracturing fracture propagation in low permeability tight oil and gas reservoirs; and (2) theoretical study and numerical modeling of fracturing fluid flowback process in shale gas reservoirs. He has been participated in a large number of Chinese natural science projects.