JRMGE / Vol 16 / Issue 2

Mechanical behaviour of fiber-reinforced grout in rock bolt reinforcement

Yingchun Li, Ammar Ahmed, Danqi Li

Show More

a Deep Underground Engineering Research Center, Dalian University of Technology, Dalian, 116024, China

b WA School of Mines: Minerals, Energy and Chemical Engineering Curtin University, Kalgoorlie, WA, 6430, Austr

2024, 16(2): 437-453. doi:10.1016/j.jrmge.2023.06.016

Received: 2023-01-13 / Revised: 2023-05-03 / Accepted: 2023-06-15 / Available online: 2023-09-04

2024, 16(2): 437-453.

doi:10.1016/j.jrmge.2023.06.016

Received: 2023-01-13

Revised: 2023-05-03

Accepted: 2023-06-15

Available online: 2023-09-04

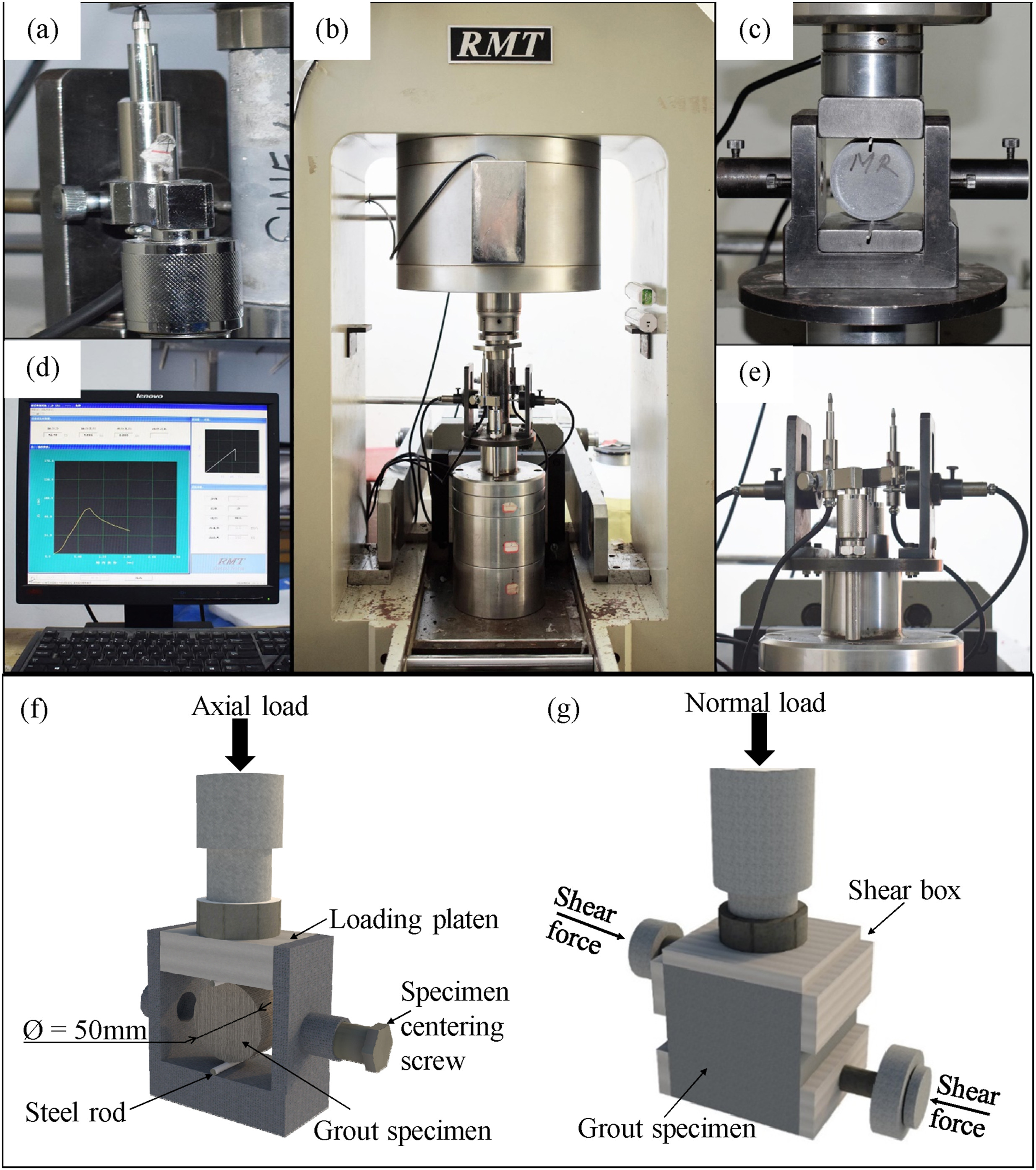

Grouted rock bolts subject to axial loading in the field exhibit various failure modes, among which the most predominant one is the bolt-grout interface failure. Thus, mechanical characterization of the grout is essential for understanding its performance in ground support. To date, few studies have been conducted to characterize the mechanical behaviour of fiber-reinforced grout (FRG) in rock bolt reinforcement. Here we experimentally studied the mechanical behaviour of FRG under uniaxial compression, indirect tension, and direct shear loading conditions. We also conducted a series of pullout tests of rebar bolt encapsulated with different grouts including conventional cementitious grout and FRG. FRG was developed using 15% silica fume (SF) replacement of cement (by weight) and steel fiber to achieve high-strength and crack-resistance to overcome drawbacks of the conventional grout. Two types of steel fibers including straight and wavy steel fibers were further added to enhance the grout quality. The effect of fiber shape and fiber volume proportion on the grout mechanical properties were examined. Our experimental results showed that the addition of SF and steel fiber by 1.5% fiber volume proportion could lead to the highest compressive, tensile, and shear strengths of the grout. The minimum volume of fiber that could improve the mechanical properties of grout was found at 0.5%. The scanning electron microscopy (SEM) analysis demonstrated that steel fibers act as an excellent bridge to prevent the cracks from propagating at the interfacial region and hence to aid in maintaining the integrity of the cementitious grout. Our laboratory pullout tests further confirmed that FRG could prevent the cylindrical grout annulus from radial crack and hence improve the rebar's load carrying capacity. Therefore, FRG has a potential to be utilized in civil and mining applications where high-strength and crack-resistance support is required.

Keywords: Fiber-reinforced grout (FRG), Steel fibers, Mechanical properties, Direct shear test, Pullout test

Article Data

Author(s) Information

Danqi Li

Dr Danqi Li is currently working as a senior lecturer at Western Australian School of Mines, Curtin University. Prior to this role, he worked as an assistant lecturer at Department of Civil Engineering at Monash University from 2019 to 2021 after he finished his PhD at UNSW Sydney in 2019. Dr Li has extensive research experience in cable/rock bolt characterization and testing and develops a novel laboratory testing facility for assessing cable/rock bolts subject to the realistic field condition. He has been involved in many research projects in the area of ground support in underground excavations and so far he has successfully received AUD650K research funding as a chief investigator from various research regimes including Australian Coal Associated Research Program and hard rock mining industry in Western Australia. To date, Dr Li has published 32 papers in prestigious journals with an average impact factor of 5.6 which is outstanding in the area of rock mechanics and geotechnical engineering.