JRMGE / Vol 16 / Issue 3

Mechanical behaviors of backfill-rock composites: Physical shear test and back-analysis

Jie Xin, Quan Jiang, Fengqiang Gong, Lang Liu, Chang Liu, Qiang Liu, Yao Yang, Pengfei Chen

Show More

a State Key Laboratory of Geomechanics and Geotechnical Engineering, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Wuhan, 430071, China

b University of Chinese Academy of Sciences, Beijing, 100049, China

c School of Civil Engineering, Southeast University, Nanjing, 211189, China

d Energy School, Xi’an University of Science and Technology, Xi’an, 710054, China

2024, 16(3): 807-827. doi:10.1016/j.jrmge.2023.08.012

Received: 2023-01-25 / Revised: 2023-05-26 / Accepted: 2023-08-14 / Available online: 2023-11-20

2024, 16(3): 807-827.

doi:10.1016/j.jrmge.2023.08.012

Received: 2023-01-25

Revised: 2023-05-26

Accepted: 2023-08-14

Available online: 2023-11-20

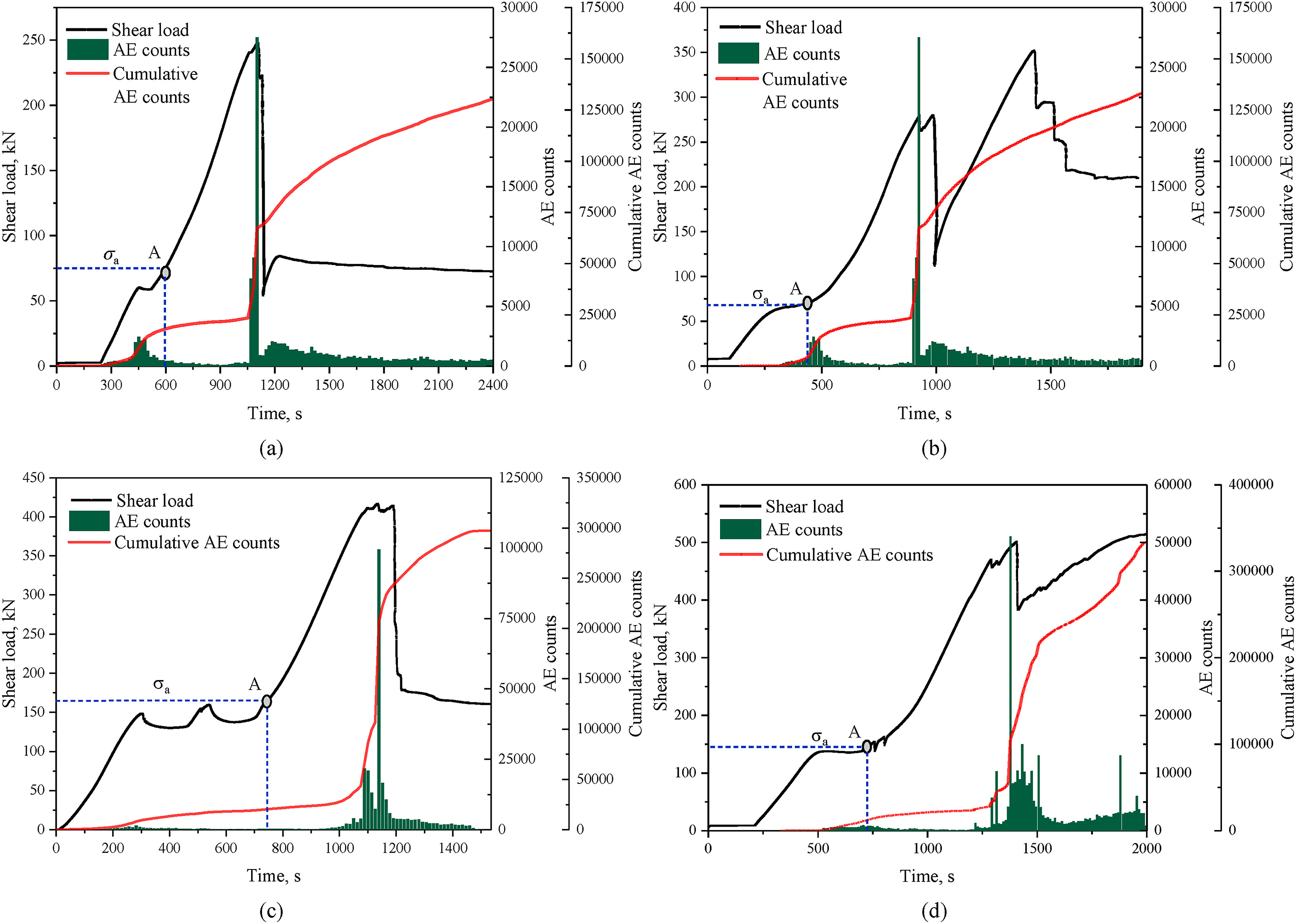

The shear behavior of backfill-rock composites is crucial for mine safety and the management of surface subsidence. For exposing the shear failure mechanism of backfill-rock composites, we conducted shear tests on backfill-rock composites under three constant normal loads, compared with the unfilled rock. To investigate the macro- and meso-failure characteristics of the samples in the shear tests, the cracking behavior of samples was recorded by a high-speed camera and acoustic emission monitoring. In parallel with the experimental test, the numerical models of backfill-rock composites and unfilled rock were established using the discrete element method to analyze the continuous-discontinuous shearing process. Based on the damage mechanics and statistics, a novel shear constitutive model was proposed to describe mechanical behavior. The results show that backfill-rock composites had a special bimodal phenomenon of shearing load-deformation curve, i.e. the first shearing peak corresponded to rock break and the second shearing peak induced by the broken of aeolian sand-cement/fly ash paste backfill. Moreover, the shearing characteristic curves of the backfill-rock composites could be roughly divided into four stages, i.e. the shear failure of the specimens experienced: stage I: stress concentration; stage II: crack propagation; stage III: crack coalescence; stage IV: shearing friction. The numerical simulation shows that the existence of aeolian sand-cement/fly ash paste backfill inevitably altered the coalescence type and failure mode of the specimens and had a strengthening effect on the shear strength of backfill-rock composites. Based on damage mechanics and statistics, a shear constitutive model was proposed to describe the shear fracture characteristics of specimens, especially the bimodal phenomenon. Finally, the micro- and meso-mechanisms of shear failure were discussed by combining the micro-test and numerical results. The research can advance the better understanding of the shear behavior of backfill-rock composites and contribute to the safety of mining engineering.

Keywords: Physical simulation, Backfill-rock composites, Shear failure, Cracking, Shear constitutive model

Article Data

Author(s) Information

Quan Jiang

Quan Jiang obtained his BSc and MSc degrees in China University of Geosciences in 2001 and 2004, respectively, and his PhD in Chinese Academy of Sciences (CAS), in 2007. He is affiliated as Professor in Institute of Rock and Soil Mechanics, CAS. His research field includes the stability analysis and optimization design for underground engineering, experimental rock/joint mechanics and geotechnical 3D printing test. He has published more than 100 papers indexed by SCI/EI, and has been responsible for more than 10 stability assessment or optimal analysis projects related to Chinese large underground caverns or tunnels, including Laxiwa underground powerhouse, Jinping II underground caverns, Baihetan underground caverns, and Jinchuan No. 2 underground mines.